3M Xtract sanding system

At Elevated Industrial Solutions, we’re proud to offer the most effective, reliable tools, components, and accessories for a wide variety of industries. We offer leading brands, including 3M, which provides an innovative abrasive system – the Xtract TM sanding platform. 3M calls it “clean sanding.”

Why is that part of their tagline? This system provides superior dust extraction and clean sanding for a wide variety of applications, all while maintaining excellent performance from an effective orbital sander.

Xtract creates cleaner work environments

The most impressive aspect of this sanding system is the ability to extract dust particles, removing them from the atmosphere while creating a cleaner, healthier work environment. Using an innovative system that places extraction holes near every single particle of dust, the sander pulls a staggering 99% of all dust, almost creating dust-free sanding. This means a cleaner work environment, less exposure to dust and fine particles, greater productivity, longer disc life, less cleaning, and fewer dust particles on the final product. This all improves the final results while making workers happier.

The system utilizes multiple features to create this impressive dust extraction. It uses a premium net disc that allows dust to pass through, while the unique hole pattern on the film disc allows dust to move from the environment into the sander with ease. No matter where a particle of dust is located, it will be near a hole for quick extraction.

The advanced extraction starts with an open-weave net structure, which ensures every particle is near a dust-extraction hole. As a user sands a material, almost all dust is sucked through the netting and into a fitted backup pad. Then it exists through the vacuum exhaust, where it can be deposited into a filter bag or dust extraction unit.

It delivers the best dust extraction on the market, without requiring the user to line up holes in the sanding unit. All of these features result in faster implementation, less time cleaning, greater productivity, and (most importantly) a safer working environment for you and your team!

Xtract has advanced performance for multiple substrates

Manufacturers of virtually all types can take advantage of the superior performance, cut rate, and dust extraction, as this system is designed for a variety of materials, including wood, metal, and composite.

The net discs from 3M perform well on multiple substrates, and they come in various grades to ensure superb performance no matter what your specific needs. There are coarser grades, which are ideal for tough surfaces, leveling filler and putty, or even the removal of stubborn coatings. People using this abrasive can also select finer grades, which can be used on final finishes or soft substrates like paint or wood.

A cut rate that sets a higher standard

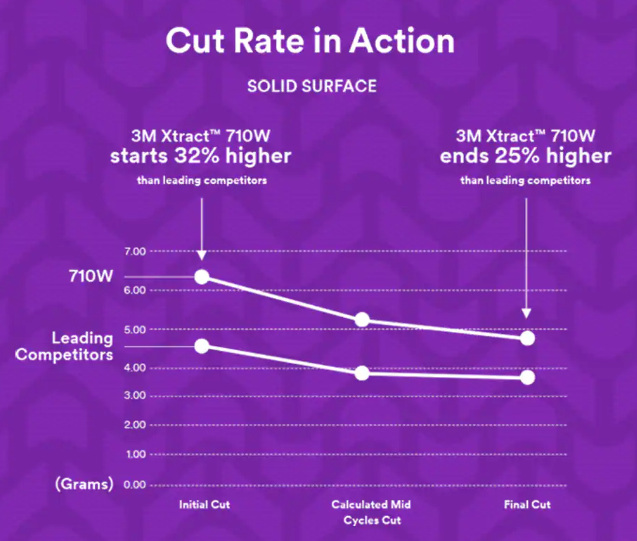

Before we continue it’s important to cover what cut rate is. Cut rate is the rate at which an abrasive removes material from a surface (wood, metal, etc.); the cut rate is sometimes called the material removal rate (MRR). Cut rates are influenced by particle size, with larger and coarser particles conventionally believed to exhibit faster material removal rates – or high cut rates. Regardless of dust extraction and performance versatility, if a sander can’t complete the job efficiently, it’s not much use, especially on a large industrial scale. The Xtract system delivers one of the best cut rates on the market.

With a new line of abrasives from 3M, the system has a superior cut rate and a longer life. On a solid surface, the 710W features 3M’s proprietary Cubitron II precision-shaped abrasive grain. Cubitron II starts with a cut-rate that is 32% higher than the leading competitor. Not only does it start stronger, but this abrasive also finishes stronger. Cubitron II features a grain that as it wears continually fractures into a sharp point, ending with a 25% higher cut rate through the life of the disc. This all results in better sanding, quicker work, and better productivity. These features make the 3M Xtract sanding system one of the best abrasives and one of the most important tools in your operation.

Xtract features to improve sanding efficiency

Available in the 3M Xtract Electric Random Orbital Sander and the 3M Xtract Pneumatic Random Orbital Sander, this sanding system could add greater productivity and performance to your sanding operations. You can also add the portable dust extractor, filter bags, and a variety of sanding discs with a range of grit sizes.

Elevated can help your woodworking needs

We have recommendations for whatever your operation is, with expertise in abrasives and sanding. Our company has been helping people like you – in the industrial, manufacturing, and construction industry – for more than 60 years. (We can’t believe we started in the 50s.)

Contact Elevated to get a demo or order the 3M Xtract sanding system and other clean sanding solutions for your manufacturing facility.