All about 3M

3M is an American corporation that manufactures and distributes industrial, home, and office supplies. It was originally named the Minnesota Mining and Manufacturing Company. Today “3M” is the official and legal name of the company.

Headquartered in St. Paul’s suburb of Maplewood, this innovative company’s employees create products for many industries, including construction, aerospace, defense, metal fabrication, woodworking, countertop fabrication, manufacturing, and healthcare.

A long history of innovation

3M was founded in Two Harbors, Minnesota, which rests on the northern shore of Lake Superior in northern Minnesota in 1902. Dr. J. Danley Budd, Henry. S. Bryan, William A. McGonagle, John Dwan, and Hermon W. Cable are credited with having founded the company together.

Since its inception, the company has revolutionized sandpaper, developed masking tape (something we take for granted these days), mass-distributed sticky notes, and created a product to protect fabrics. The team also helped launch new products to help in the war effort during WW II.

During COVID, the company’s personal protective equipment (PPE) was in high demand. Healthcare workers and first responders were given priority as they dealt with patients and those needing care. To help more people and the government, the company ramped up production to save more lives.

Well-known brands

3M brands are quite literally household names. Any time you grab a piece of tape, chances are good it’s Scotch tape. When you add a sticky note to save information on your book, you might be grabbing a Post-it note. 3M owns more than 30 brands, including Scotch, Scotch-Brite, Scotchgard, and Post-it.

A vast array of products

3M currently offers a vast assortment of products — more than 60,000 — while serving numerous industries. Their products include:

- Abrasives

- Adhesives

- Building materials

- Coatings

- Coating and finishing spray equipment

- Polishes

- Electrical supplies

- Sheeting

- Insulation

- Lubricants

- Medical supplies

- Signage and marking materials

- Tapes

They literally provide everything from dental aligners to items to make semiconductors. 3M literally has it all.

Our highlights

It’s impossible to name every product, but we can highlight a few of our favorites ….

Green masking tape

Extremely popular, 3M Green Masking Tape is a product built on durable yet easy-to-use crepe paper, which allows for swift and accurate tearing. This UV-resistant tape was designed specifically for high sunlight exposure; it’s ideal for outdoor paint masking, temporary use on outdoor signs, and protecting various items during paint and construction projects. It also serves in many capacities as regular tape.

Our customers love it for its ease of use, versatility, durability, and affordability.

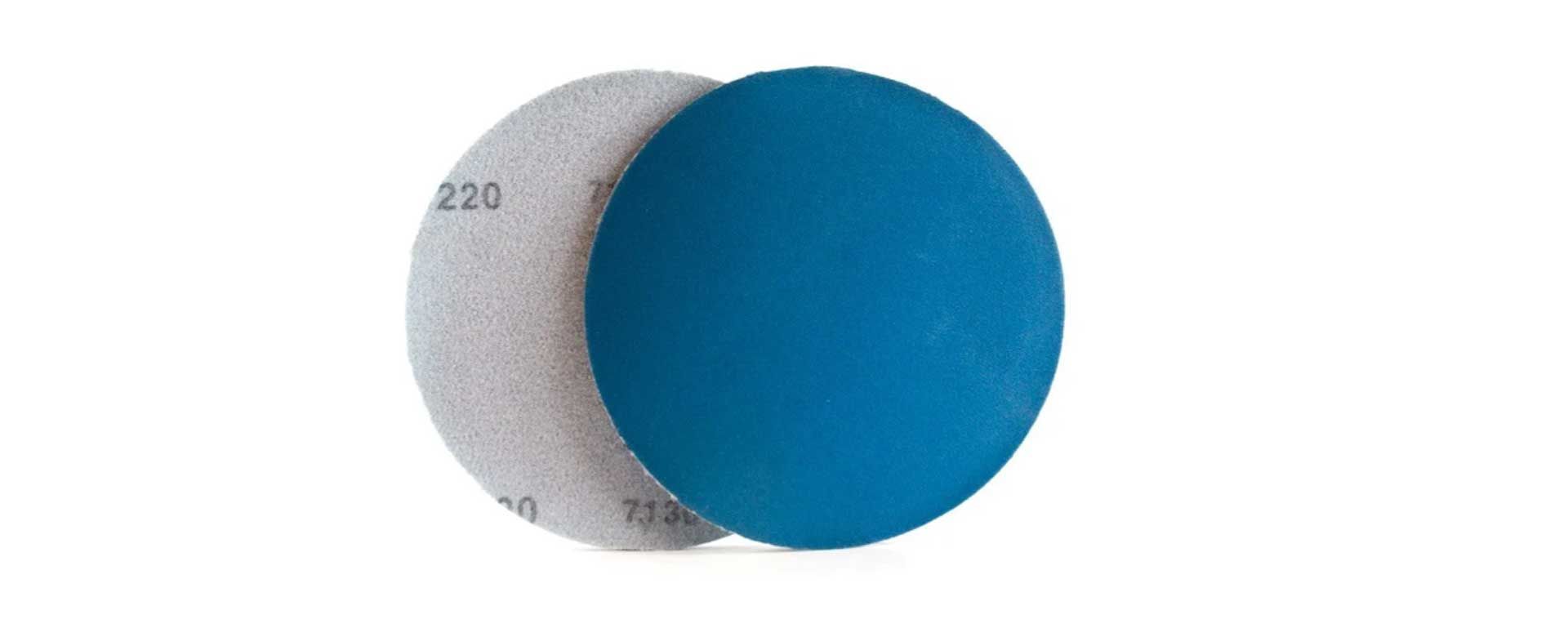

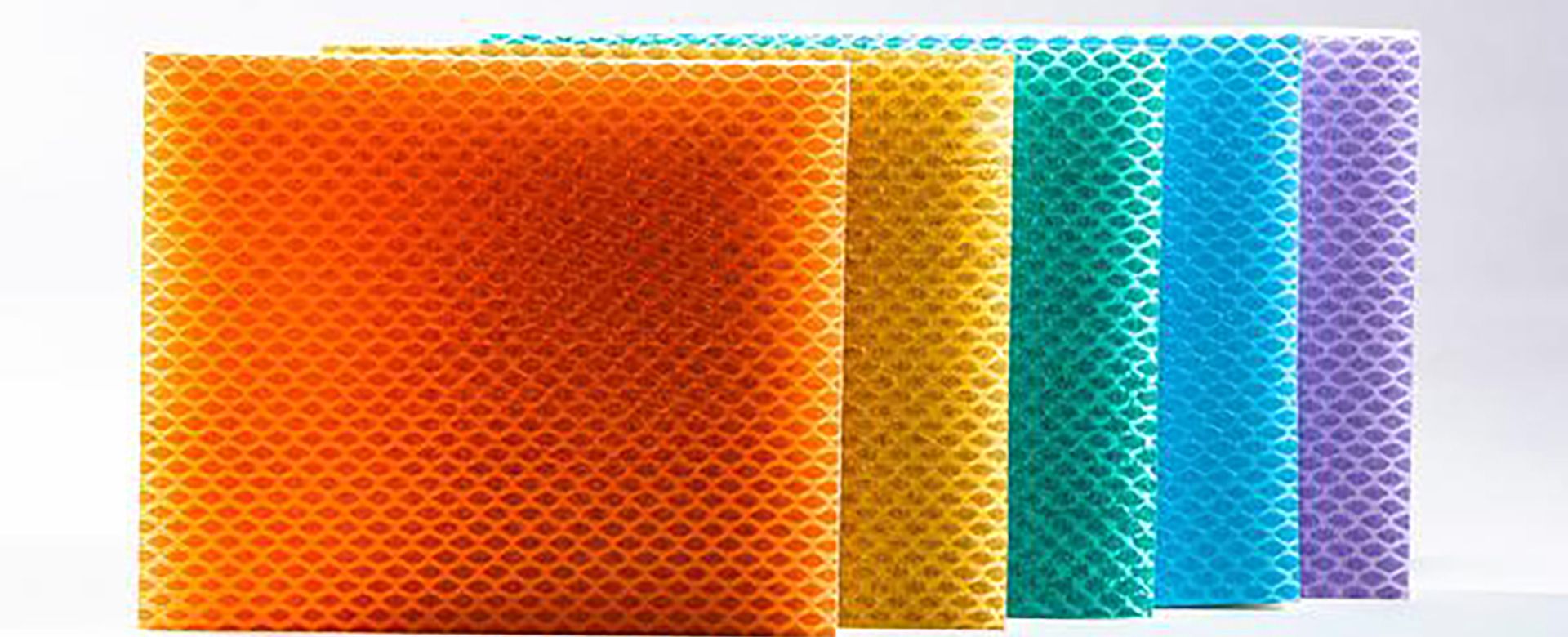

Xtract sanding system

Sanding is an important phase for various manufacturing processes. 3M has created “clean sanding” with the Xtract sanding system, which enhances product surfaces while creating a clean working environment. The system uses extraction holes throughout the sanding surface to remove 99% of all dust, resulting in a cleaner work environment without sacrificing product quality.

It’s a great solution to prevent dust from impacting your workforce’s health.

VHB tape

Standing for “Very High Bond,” 3M’s VHB tape is a two-sided adhesive that has been serving users since 1980. It was originally used to secure panels to ambulance frames, a clear demonstration of this product’s incredible bonding strength. The tape is now used in numerous automotive, furniture, and industrial applications.

Performance Industrial Spray Gun HVLP System – (26878)

This durable system was built for industrial painters. It’s lightweight, making it easy to carry and ensuring a consistent spray. The spray gun’s trigger was optimized by kinesiologists to increase ease of use, preventing hands from getting tired and impacting a finish. This system is also versatile, spraying from a pressurized source or a gravity cup. Adding to its versatility, replaceable nozzles enable you to change sprays and make clean-up easier.

Proud distributor of our partner

Didn’t see your favorite product on our list? Don’t worry. Elevated has a full range of 3M products for virtually every industry.

We take pride in providing 3M and other high-quality brands. We supply solutions that help your business be more efficient and effective, including saving time, reducing overall costs, improving productivity, increasing quality, etc. Your goals are ours. It’s why we call ourselves your partner.

Of course, if your heart is set on a specific brand, such as 3M, we won’t turn you down. 3M acts as our partner to help train your staff and get the best product possible at a reasonable cost.