What are hook and loop as well as reclosable fasteners?

Hook and loop fasteners as well as reclosable fasteners secure things. Haven’t heard of this technology? You probably have! You may know this fastener style by a brand name: Velcro. Like “Kleenex” many people confuse tissues and Kleenex. (Hand me a Kleenex!) In the same way, people also use Velco and hook and loop or reclosable fasteners interchangeably.

The history of Velcro

The Smithsonian indicates a Swiss engineer named George de Mastral was walking with his dog when he noticed burrs were stuck in his clothing and to his pup. Intrigued by how the burrs clung to fabrics and hair, he examined them under a microscope. To his surprise, they had tiny hooks that attached themselves to loops in the fabric of his clothes. Inspired, he thought they had practical uses in manufacturing and decided to create them himself.

After years of experimentation and development, de Mestral patented his invention in 1955, and called it “Velcro” (a combination of the French words for velvet and crochet). The Velcro fastening system quickly gained popularity and found a wide range of applications in various industries.

Since that time, other companies have created their own version of “Velcro.” However, the brand name is owned by Velcro IP Holdings LLC and trades as Velcro Companies, a privately held company in the UK.

Why are hook and loop as well as recloseable fasteners used?

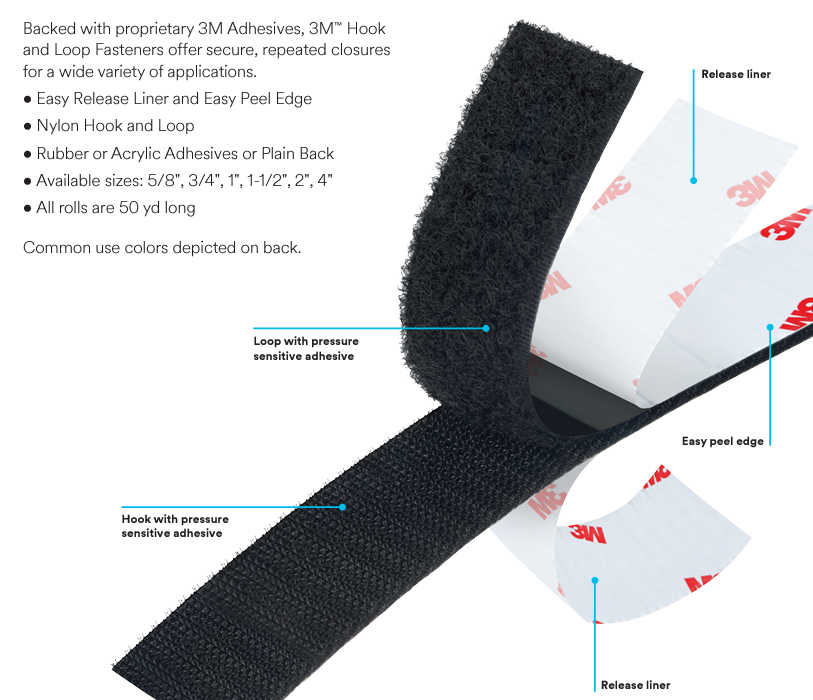

According to 3M, one of the leading suppliers of this technology, hook and loop and reclosable fasteners are great for people who need closure to go on easily but securely, be conformable to your part shape, and stay closed until you’re ready for it to easily peel open. Here are just a few reasons people choose hook and loop fasteners for their projects.

- Ease to use. Hook and loop fasteners are simple to use. They consist of two components: tiny hooks and small loops. Pushing the two components together creates a secure and temporary bond, and pulling them apart releases it. This simplicity makes them accessible to people of all ages and abilities. It’s why they’re used on medical devices, such as leg braces.

- Reusability. Hook and loop fasteners are designed for multiple uses. They can be opened and closed repeatedly without impacting the effectiveness of the hold. This reusability makes them ideal for applications where you need to attach and detach items frequently.

- No other tools are required saving time and resources. Unlike traditional fasteners such as screws, nails, tapes, or adhesives, hook and loop fasteners don’t require hardware for installation. This saves time and eliminates the need for drilling holes or using adhesives that can damage surfaces.

- Versatility. Hook and loop fasteners are available in various sizes, strengths, and colors, making them versatile for different applications. Industries such as clothing, footwear, automotive, aerospace, and healthcare all use hook and loop.

- Safety. In some applications, particularly in child and medical products, hook and loop fasteners are preferred because they eliminate the risk of sharp edges or protruding parts. That reduces the likelihood of injuries and ensures children and medical products are safe.

- Temperature and chemical resistance. Depending on the specific type and brand, hook and loop fasteners can be resistant to various environmental factors, including temperature extremes and chemicals.

Who uses them?

Everyone. No doubt, you’ve used hook and loop or reclosable fasteners in your personal life. As noted above, many industries from aerospace to healthcare to textiles use hook-and-loop technology as well as recloseable fasteners. And they’re used on products from purses and shoes to transportation seating and signage.

Types and brands

There are varying types of hook and loop as well as recloseable fasteners from a number of suppliers. Here are just a few of our favorites by the trait.

For strength, 3M has Dual Lock (see right), which provides more strength than other brands. 3M uses “mushroom heads” for what they indicate is “5x the tensile strength of hook and loop fasteners.” It also mates to itself, so you don’t have to worry about which side you’re using for your project. Despite how well it holds, this technology can still be pulled apart without hardware. These come in a variety of colors and sizes.

3M also provides Scotchmate Hook and Loop, which is strong but can be sewn into textiles or uses adhesives to secure it to surfaces.

There are flame-resistant (with or without adhesive) options, including the SJ3419FR (Hook) and SJ3418FR (Loop). There are even high-performance choices that hold up under extreme conditions, such as SJ3572 (Hook) and SJ3571 (Loop).

For just about any need, there’s a fastener you can use!

Elevated can help with hook and loop fasteners

As with most projects, hook and loop fasteners may not be right for you. Of course, your project’s purpose and goals weigh into whether you use them and which type you use. Elevated carries a wide array to meet the needs of your project. We have industrial solutions specialists who can help you decide if it’s right for your company, and which brand and option to get.