It’s a new year, and the economy by all accounts is good. Inflation is cooling, disposable incomes are rising, and the economy expanded in 2023 by 3.3%, according to Axios. That means 2024 should be interesting for the construction and manufacturing sectors.

Both industries face similar challenges, including labor shortages and high interest rates. But there are also numerous positives coming into 2024, such as a stronger supply chain, more support for infrastructure and infrastructure building, and the gradual return of American manufacturing jobs.

To ensure you’re not caught unawares, we have a list of trends in 2024 for both construction and manufacturing.

Efficiency and sustainability drive both industries

If you look around, you’re already seeing changes in both environments — AI, robotics, and more. These technology, labor, and market trends will continue. But one of the most impactful trends, which will affect all aspects of the economy, is efficiency and sustainability.

Companies are pressured from inside and out to enhance their sustainability practices (meeting greener work practices and climate-related goals) while driving down costs. These forces will drive decision-making across construction and manufacturing, as companies seek to become leaner and more efficient in all aspects. For construction, which has more information below, it includes modular — a potentially faster and cheaper way of building.

Supply chain continues to improve

Both the construction and manufacturing industries have been impacted by supply chain issues. Since the pandemic in 202, kinks and outright breaks in the chain caused delays, material shortages, and complete stoppages for many manufacturers and builders. This is already easing and will continue to ease as long as there aren’t unforeseen incidents from Mother Nature or global conflicts.

There are still plenty of bottlenecks for shipping and distribution, but overall products and materials are becoming more available. As the Hartford says, “There is hope on the horizon as professionals have seen the supply chain delays begin to stabilize.”

Although overseas conflicts and the potential for severe weather may affect the supply chain, overall it should run much smoother in 2024 compared to previous years. Of course, you can always work with your industrial supply team on safety stock to ensure the products you need are always available.

Labor

Worker shortages continue

In the current economy, “labor shortages” is an all-too-common phrase. Unfortunately, business owners and managers in virtually every sector, including construction and manufacturing, will continue to deal with finding the right people to fill vacancies.

In 2023, there was a labor shortage of over half a million people in the construction industry alone. How bad will it be in 2024? Will be get better or worse? According to the U.S. Chamber of Commerce, a “smaller workforce will define the economy in 2024.”

Both construction and manufacturing have journeymen and journeywomen who are retiring without people to replace them. These problems are coming to a peak at a time when large construction projects and manufacturing are increasing and there’s more demand for American manufacturing. In concentrated areas, there is a massive need for workers, which means increased competition for labor.

Retraining and retaining workers

Another important trend in 2024 will be the increased need to “reskill” or “upskill” workers. In some cases that means taking an employee from one part of the company and training (at a trade school, college, or conducting training in-house) them on a different part of the business.

Companies will need to get creative about retaining their workforce, preventing them from going to the competition. This retention strategy may include pay increases, bonuses, more vacation time, flexible hours and locations (hybrid, remote, or in-person working), in-company childcare options, and other perks.

Union strikes

As the balance favors the employee over the worker, 2024 could bring more strikes to manufacturing and construction. After the successful labor strike for UAW (United Auto Workers), more employees may try to gain pay or other incentives. Those fields that haven’t unionized in both industries may do so, too. the retention strategy above may help avoid issues and keep workers happy and at your company.

Manufacturing

“Reshoring”

Possibly the most positive trend for 2024, it’s possible that manufacturing will start in earnest to “reshore.” This simply means that manufacturing jobs, a crucial part of the overall U.S. economy, are starting to return from overseas. This would strengthen the nation’s security while also providing quality jobs.

Reshoring takes many forms, not just critical American jobs. It creates a localized and responsive manufacturing ecosystem, improves the supply chain, and reduces the nation’s dependency on foreign producers (such as China).

Increases continue

According to Deloitte, “In 2023, the US manufacturing industry capitalized on the momentum generated by three significant pieces of legislation that were signed into law in 2021 and 2022 — the Infrastructure Investment and Jobs Act (IIJA), the Creating Helpful Incentives to Produce Semiconductors (CHIPS) and Science Act, and the Inflation Reduction Act (IRA). As of July 2023, annual construction spending in manufacturing stands at US$201 billion, representing a 70% year-over-year increase and setting the stage for further industry growth in 2024.”

Of course, this is heavily reliant on a variety of factors, including getting the right people in the right jobs, ensuring the supply chain is stable, and finding efficiencies.

Construction

Overall increases

In the construction industry, most experts predict increased total spending. This increase in spending will be specific to certain areas, sectors, and niches, but overall spending should be positive.

According to Deloitte, construction spending reached $1.98 trillion by August of 2023, which was a 7.4% increase since the previous year. This increase was driven by non-residential construction. In the same time frame, residential construction spending was down 3%. This trend is expected to continue; although, there is hope that with a good economy and stable supply chain, spending in residential construction will recover. Major cities across the U.S. need additional housing, including affordable housing options.

A decline in commercial property value?

Real estate, which is tied at the hip with construction, has seen declines in building commercial buildings. According to the American Institute of Architects, there has been weak demand for property in most commercial sectors. This includes multifamily housing, commercial, and industrial property. Unsurprisingly, office property has seen the biggest decline; this area has dropped in value by almost 15% in the past year, a trend that will likely continue with the changing nature of work.

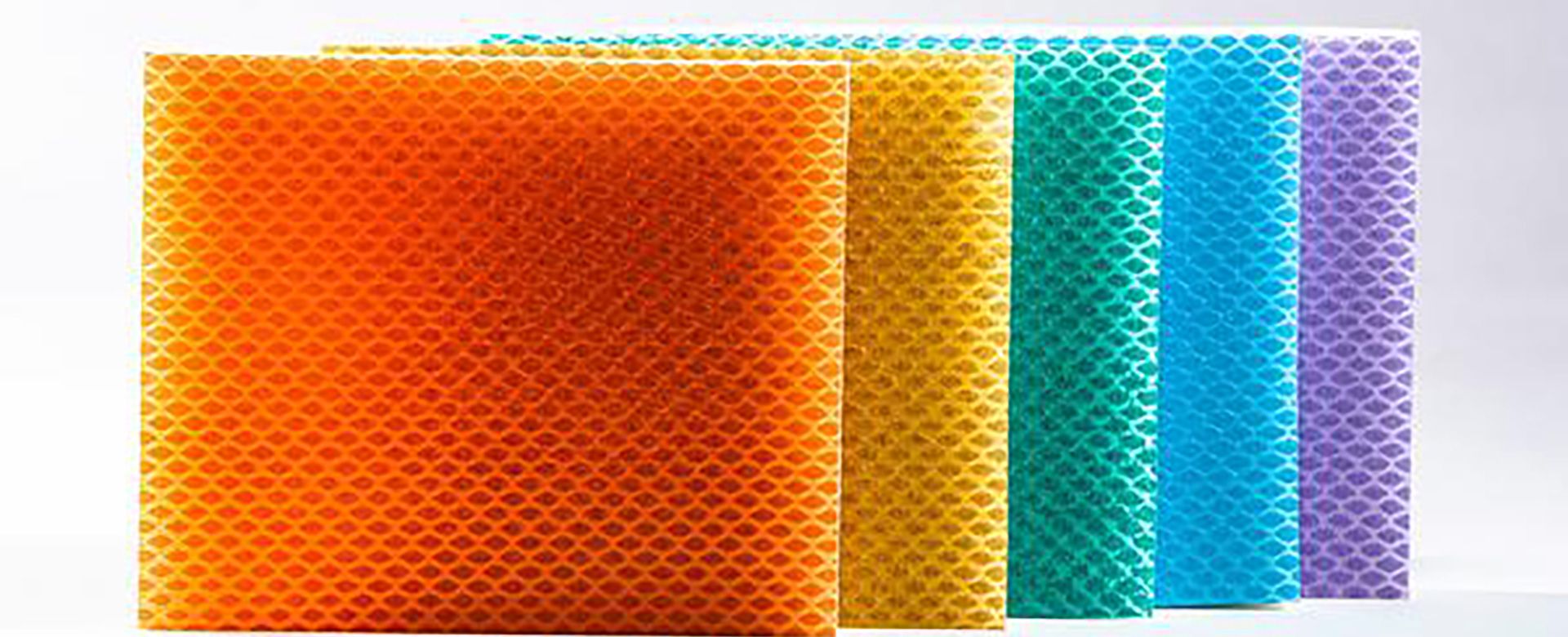

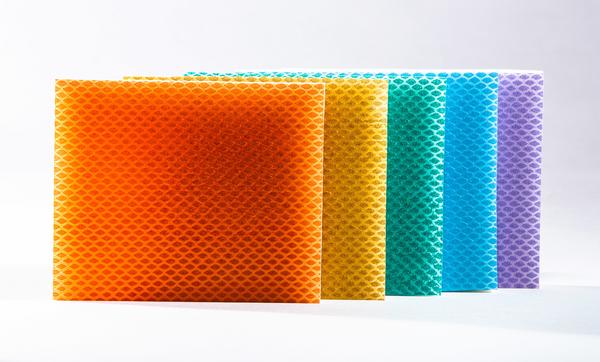

Prefab and modular continue to rise

Despite declines in residential construction spending, affordable prefabricated and modular housing will likely rise.

The real estate industry, which is heavily influenced by interest rates, available supply, inflation, and other factors, will likely see an increase in overall demand. Many are predicting a surge in real estate because of pent-up demand, which could be released in 2024. This demand will likely drive an increase in prefabricated and modular housing.

After years of economic uncertainty, inflation, and rising interest rates, many individuals and families will finally have the chance to move into homeownership. A blizzard of new projects will likely include numerous prefabricated and modular homes.

This increase, however, will likely be regional. Certain areas will see sharp increases in modular homes, while others may see none at all. Regions, states, and counties with positive job growth will see the biggest demand, while declining areas will see little to no demand for prefabricated and modular houses.

Material costs, labor shortages, mortgage rates, and increased market inventory could cool modular and prefabrication, but overall the signs are pointing to rapid growth.

Are you ready for 2024 and beyond?

Are you ready for the challenges and opportunities of 2024 and beyond? We can help! Our goal is to make your business more efficient and effective by suggestions solutions — including industrial supplies, coating and finishing equipment, compressed air systems and services, and assembly tools.