Tech notes: yield control summary

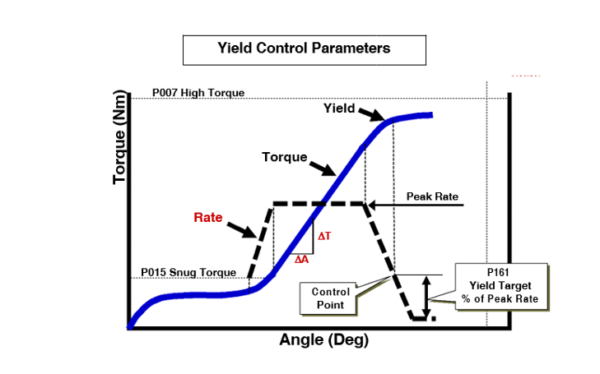

Monitoring the rate of change of Torque vs. Angle provides a new dimension in the control of the fastening process. With Torque Rate Control an increase in this rate to a specified level can indicate an event in the fastening process, such as the seating of a fastener, which can be used as a starting point for another fastening step, such as backing out a certain amount. Monitoring this Torque Rate can also allow us to determine the yield point of each fastener during the fastening process.

Fastener yield control

The process of tightening a fastener involves stretching, or preloading, the bolt to allow it to store enough force to hold the assembled parts together. Preloading the bolt to a higher load will hold the assembled parts together with more clamp force. Preloading a fastener to the yield point of the bolt material will provide the maximum clamp force possible from each fastener. Preloading a fastener to its yield point can also assure a static loading condition for the fastener when the service loads may exceed the preload available with other fastening methods, thereby reducing the risk of fatigue failures.

A bolt acts as an extension spring. Within its elastic region, any increase in deflection will produce a proportional increase in load. But once the bolt is stretched beyond its elastic limit and into the plastic region, the same incremental amount of deflection will produce a proportionally smaller increase in load. As long as the bolt is preloaded within its elastic limit, no permanent deformation of the bolt will occur. When unloaded, it will return to its original length. But once the bolt is deflected beyond its elastic limit and into the plastic region, permanent elongation will occur. The yield point of a material is traditionally defined as the point at which 0.2% permanent elongation occurs.

When tightening a fastener, the applied Torque is directly proportional to Load, and the Angle of rotation is directly related to the Deflection through the thread pitch. By monitoring the dynamic Torque and the Angle of rotation during a fastening cycle (beyond the initial free run-down and pull-up phases of a fastening cycle), the rate of change of Torque vs. Angle is directly related to the rate of change of Load vs. Deflection of the bolt material, thereby providing a convenient method for monitoring the onset of the elastic limit of the bolt material. The QPM controller software can now detect this fastener yield point and stop the fastening process when this occurs.

View Stanley Assembly Technology’s Yield Control Summary to learn more about torque rate control, fastener yield control, parameters for each as well as limitations and recommendations for better yield control.

Elevated can help

We have experts who provide ideas and information to help your team use tools, including precision tools, better. We can also recommend, repair, and calibrate tools to ensure you get a return on your investment. Plus, we have compressed air systems and service, coating and finishing systems, and industrial supplies to keep your plant operating efficiently and effectively.

Connecting whip cables to tools

Beier high-performance replacement cables