Compressor life cycle cost

Many factors go into the total cost of investing in a compressed air system. Focusing on just the upfront expenses can hurt your company and cost thousands. For example, energy usage alone can outpace the initial price of the compressor in just a couple of years. These factors make up the overall return on investment (ROI) you’re getting when you think of budget costs.

Here are 4 categories to consider when thinking about the life cycle cost of your compressed air system. It’s especially important to consider as the purchase price is only a fraction of the overall cost — over the years — of your machine.

Purchase price

The initial cost of the compressor can vary greatly. Larger manufacturers may use more expensive equipment to reduce reliability issues and increase productivity. Getting the right machine for your environment is crucial – the durability needed, correct horsepower, etc. (The right vendor will never give you more horsepower than needed.)

Compressor parts and service

Getting a brand that’s known for its reliability is a good start. Some brands are definitely more durable than others. These high-performance machines will cost you less, generally, in parts and service.

But service is an important component, especially getting service in a timely manner. Vendors who are available 24/7, 365 days a year that you can rely on when you need them is crucial. You also want certified technicians who are experienced with your compressor, no matter the brand.

The most expensive issue comes from not servicing your compressor at all. It can cause additional wear and tear on your compressor, increasing operating costs (more parts and service). Worse, it can also potentially shut down your facility, halting production. (We’ve seen this happen!)

Energy costs

It’s no secret that industrial air compressors consume a lot of energy. Many modern compressors are highly efficient and will produce much more air for less money. Kaeser, for example, is known for its high performance. Considering energy is the largest cost, this should be a primary focus when purchasing a new compressed air system.

The right vendor will help you find ways to save money, even if you’re purchasing the most expensive brand.

Additional factors

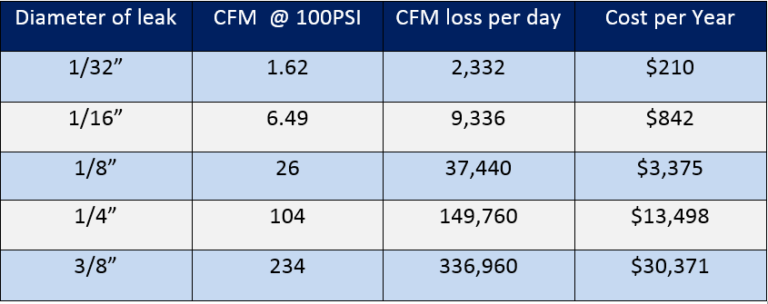

Additional factors include load/unload cycle time, air leak losses, non-production operation, system pressure set points, and individual components that can make a difference in the cost of your compressor’s operation.

Elevated is there for the lifecycle of your compressor

Elevated has certified technicians available 24/7. Parts are in stock. We offer ultrasonic leak detections, air audits, and scheduled maintenance to save you time and money. In other words, we work to eliminate any downtime. Let us make recommendations on your compressed air system or service needed.