- Industrial Supplies

- Coating & Finishing Systems

- Compressed Air Systems

- Assembly Tools

- Industries Served

- Aerospace & Defense

- Automotive & Specialty Vehicles

- Cannabis

- Construction & General Contracting

- Countertop Fabrication & Installation

- Food Processing

- Healthcare & Medical

- Logistics & Distribution

- Manufactured Building & Housing

- Manufacturing

- Metal Fabrication & Steel Works

- Millwork, Cabinetry, & Woodwork

- Packaging

- Pallets & Containers

- Plastics

- School Systems & Universities

- Signage

- Signs & Displays

- Textiles & Nonwovens

- Window & Door Installation

7 common air compressor maintenance mistakes

When it comes to your business, compressed air represents a significant operating cost. Between the compressor, system, installation, and maintenance, your compressed air system can cost tens of thousands or hundreds of thousands of dollars (depending on the size of your facility). But did you know you may be wasting money through common air compressor maintenance mistakes?

Mistake 1: not purchasing a cost-efficient, easy-to-maintain machine

A lot of factors go into the entire cost of compressed air systems, not just the initial price of the compressor. These factors include the lifespan of the compressor, maintenance costs, frequency of maintenance, and energy usage. These costs will far outweigh the price of the compressor, so it’s important to purchase a high-quality and reliable compressor that is easy to maintain.

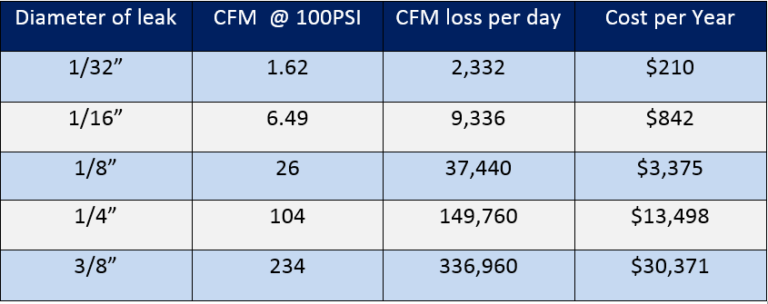

Mistake 2: air leaks

Air leaks, whether you’re ignoring it or don’t know it, can cost you thousands. Your compressed air system will work overtime to keep up with demand, increasing wear and tear on your compressor as well as energy costs. Ensure you do not have air leaks by performing routine leak audits.

Mistake 3: infrequent inspections

Your compressor receives scheduled maintenance, but maintenance may not cover everything that happens to your compressor. Wear and tear, dirt, and broader maintenance needs may be causing your compressor to run longer to meet air demand. (Your expert service technicians should be recommending how often your compressor needs maintenance and other audits based on your environment and runtime.)

By performing inspections, variables such as temperature, humidity, dust, and wear and tear on your compressor will be managed which will improve efficiency.

Mistake 4: compressed air pipe

Certain piping materials can promote contamination, leaks, and pressure drops. Regardless of the material, the pipe will eventually need to be cleaned of debris and eventually replaced. Failure to clear this debris can lead to inefficiencies and additional issues for air tools and your compressor. SmartPipe+ by Kaeser does not promote contamination which increases the lifespan of the piping and system.

Mistake 5: air demand

It is very common for companies to overestimate or underestimate air demand. Often times this underestimation leads to needing new equipment. By performing a demand analysis you’ll able to identify the exact amount of air you need even across different departments. If your equipment has already been purchased and is not meeting demand, oftentimes you do not need to replace your compressor. Upgrading tank size and reducing inefficiencies with an air management system will provide additional air at a lower cost, helping you meet the required demand.

Mistake 6: training staff

At some facilities, machine operators are less experienced and less knowledgeable of the compressed air system than management. Providing additional training to operators will help provide more air at a lower price, help spot maintenance issues before they arise and reduce stress on your compressor.

Mistake 7: data collection

Being able to spot issues early will prevent issues from becoming worse, downtime repairing the machine, and time spent figuring out what went wrong in the first place. Collecting data on your compressed air system with help identify future issues. Once again having well-trained staff and collecting data will help identify potential issues before they get worse.

Elevated doesn’t make maintenance mistakes

Getting Elevated service means you won’t have these common mistakes. Instead, our team of experts will do everything necessary to keep your compressed air system running at peak efficiency. Our team is certified and can train your personnel as well as deliver just about any data you need. Plus, we work with energy companies to save you money. For an air demand analysis (ADA), ultrasonic leak audit, SmartPipe+ information, or maintenance, contact our team. We’d love to help!

-

December 2, 2014

December 2, 20147 deadly sins of compressed air

When putting together a compressed air system, temptation is all around you. You want the best system, but having the best doesn’t mean grabbing w… -

January 8, 2015

January 8, 2015Get your compressors ready after the holidays

The holidays are over and for many plants that mean seasonal shutdowns or lower production demands are also a thing of the past. While everyone is… -

February 4, 2015

February 4, 2015Don’t get fooled – go with the real deal (Kaeser and dealer expertise)

We’ve all been there. I would wager we’ve all done it. When it comes time to get an oil change or replace our windshield wipers, we want to go for…