What is CAGI … and why is it awesome?

If you’re a plant or facilities manager, you may already know all about the wonders of CAGI, but assuming you’re new to it CAGI has changed the world of compressed air.

What is CAGI?

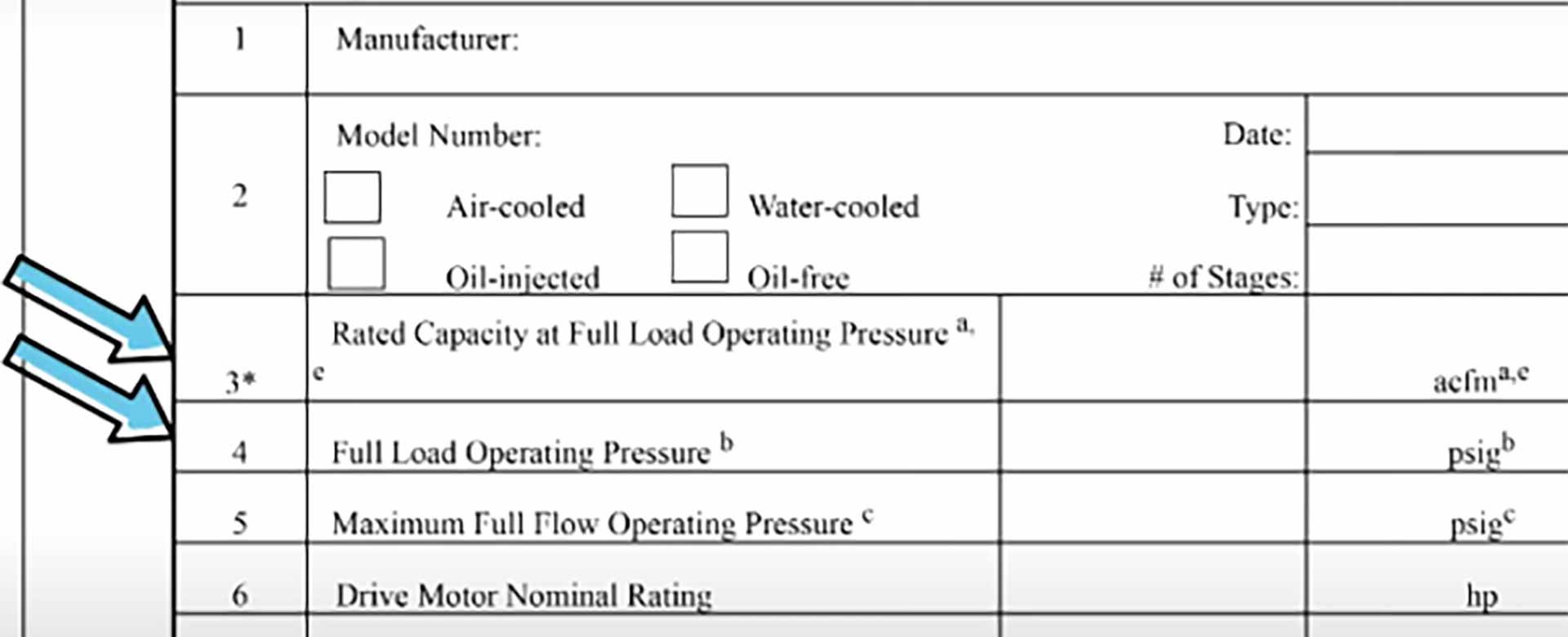

CAGI stands for the Compressed Air and Gas Institute. On the CAGI website, it indicates it’s “the united voice of the compressed air industry, serving as the unbiased authority on technical, educational, promotional, and other matters that affect the industry.” It’s an organization that tests and standardizes information to make it easier to understand.

Why is CAGI awesome?

CAGI verifies compressor claims using a third-party testing program. According to CAGI, the program provides you with “reliable and verified performance data for rotary air compressors (5-200HP) and refrigerated air dryers (50-1000 scfm).”

And CAGI compares data, making it easier to read and understand one compressor vs. another through an efficiency rating value on its compressor data sheets – isentropic efficiency.

What is isentropic efficiency?

Utilizing isentropic efficiency is similar to using a Monroney window sticker when purchasing a new vehicle. For example, the Monroney sticker explains the projected miles per gallon of the vehicle, price, features, and other useful information that helps assist buyers when purchasing a new vehicle.

Isentropic efficiency incorporates operating pressure and greatly simplifies the process of comparing the efficiencies among several like-sized compressors each having slightly different full-load operating pressures. For example, for the same horsepower compressors, one sheet may show 125 psi operating pressure and another may show 130 PSIG, so comparing isentropic helps equalize the comparison. This video, developed by CAGI, explains how specific power is converted to isentropic efficiency.

Elevated can help provide CAGI data

If you’re considering an air compressor, your sales engineer can provide information about it, including comparing it to other compressors. For more information, talk with us about your compressed air system needs. We have specialists available to assist you with calculations, installation, pricing, and more.