Air compressors are the lifeblood of many facilities – keeping your business going. They help you deliver your company’s products on time and on budget. Compressor Station Audits can assist too, in ensuring you’re using your equipment to the best of its ability.

Together, preventive maintenance and audits (air compressor service), keep a facility running.

Preventive maintenance

Did you know that you should be having your air compressors serviced at least once a year or for every 2,000 – 3, 000 hours of service? In addition, extreme weather conditions – caused during winter and summer – are great times to get your air compressor serviced.

At a minimum, compressors need a variety of routine maintenance:

- Fittings and belts tightened and inspected

- Oil changed

- Filters changed

- General inspections

- Cleaning of all coolers and drains

- Collection of oil samples for testing

- Recording amp draw

- Recording voltage

- Checking for abnormal vibrations and noise

- Injection and discharge oil temp

- Lubricating drive motor bearings

If you’re behind on your maintenance or considering an audit, here are a few good reasons to invest in maintenance … before it’s too late.

Save money on replacing a compressor as well as get more efficiency

It probably goes without explaining that preventive maintenance can save money in the long term. A new air compressor, being replaced after not maintaining your old one, is costly.

What often happens, though, are air compressors being used inefficiently due to lack of maintenance. One auto shop couldn’t keep up with customer demand due to delayed maintenance.

Prevent shutting down your plant or handling costly repairs

When air compressors aren’t serviced regularly, they become more apt to break down or quit completely. Of course, when an air compressor breaks down, the facility could come to a halt. Shutting down operations costs your company time and money, even potentially impacting your customers.

But it goes beyond stopping or slowing operations. The labor costs for emergency repairs can be expensive, too. Although Compressed Air Technologies handles emergencies, including middle-of-the-night repairs, we don’t recommend customers wait for that scenario.

Prevent injured workers and fines

You also probably know that if compressors are mishandled or misused, they can be dangerous, causing serious issues. Those issues can vary wildly from hearing damage to killing a worker.

If a worker does become injured on the job, including his hearing damaged, they can file a worker’s compensation claim and potentially even sue your company. One law firm indicates their median settlement for hearing loss is around $55,000.

OSHA has standards for how air compressors are used in facilities, even where they’re used. Violations of those OSHA standards can be expensive; OSHA fines are up to $70,000 per violation.

Audits

Audits are an important part of the equation for keeping your facility running. Typically, managers ask for an audit before adding compressors. Audits provide a snapshot of overall controls, get an idea of peak usage and capacity, and more.

Audits are used for the following:

- Weaknesses in your existing system, including leakage

- Inefficiency in the compressors you’re using, including too much horsepower

- Providing guidance on reconfiguring your current system for better airflow

Save money from buying another compressor

By receiving an audit, you can identify whether you really need an additional compressor. Compressed Air Technologies technicians often see managers ready to buy a new compressor when one isn’t necessary. Many times, air compressors aren’t being fully utilized. Technicians and engineers can help you reconfigure your setup to ensure maximum efficiency.

Not purchasing an additional – and unnecessary – air compressor could save thousands of dollars. For example, Kaeser has a case study on one audit, where they identified a furniture company that was wasting $600,000.

Save money on energy and energy consumption

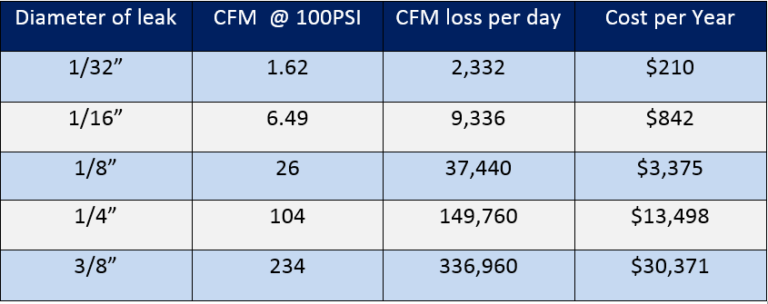

Audits can point out leaks to reduce them as well as ensure energy is being used efficiently. Even if energy consumption isn’t an overall goal of your company (such as those seeking ISO certifications or meeting tight environmental standards), it can save money. After all, the more compressors you’re using, the more energy you’re consuming.

One Kaeser case study indicates one company saved (with a utility rebate) $78,031 in the first year alone. Audits are a fraction of that cost.

Audits + maintenance together

Audits + Maintenance – it’s the formula for running an efficient facility. Together they can save you money. They keep workers safe, prevent unnecessary fines and lawsuits, and keep your plant moving.

At Elevated Industrial Solutions, we enable you to meet customer demands on time and on budget. Our technicians have a combined 60+ years of experience. And although we handle late-night emergencies, we provide – and can help you schedule – regular maintenance to prevent catastrophes at your facilities.