7 tips for better, more efficient sanding

When done right, sanding can create an outstanding final product. Simple as it may seem, sanding can be surprisingly complex and challenging. That’s why Elevated has seven tips to make your company’s sanding efforts more effective .…

1. Find the ideal tension

To avoid problems like belt folding, belt tearing or ripping, and joint failure, you need the right (or Goldilocks) tension; not too much, not too little. The ideal range will depend on many factors, including the material of your belt.

Paper, cloth, and polyester all require a different range:

- Paper: 45-55 psi

- Cloth: 55-65 psi

- Polyester: 65-85 psi

Find the right abrasive tension before starting, and if you experience issues like tearing or folding, adjust the tension and make slight adjustments until the system runs perfectly.

2. Maintain your machine for maximum belt longevity

Sanding belts are expensive, so you need to make them last as long as possible. The first step is to maintain your machine. With proper maintenance, your machine will not create unnecessary wear on the belt itself. (Of course, this doesn’t hurt machine longevity either.)

Once maintenance is complete, verify that the belts are running at the right tension for the best removal rate. It also helps to ensure the machine is set to the correct feed rate. Nothing will make your belts last forever, but these steps will help them last a little longer.

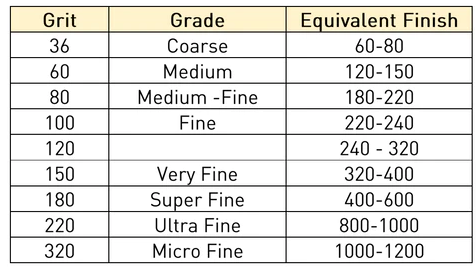

3. Always select the right grit for the job

The most important factor for stock removal is the selected grit. What grit you use will impact the efficiency of your sanding as well as the quality of your final product.

Selecting the right grit can be complicated, but most can select an ideal grit based on the application requirements:

- Abrasive plaining: 24-40 grit

- Heavy stock removal: 50-80 grit

- Cutting/surfacing: 100-150 grit

- Finishing: 180-320

Essentially, as you move from beginning to end, you should be using a progressively finer grit. (A higher number.)

4. Only skip one grit at a time

You need to move from one grit level to the next in sequence. It may be tempting to save time and money by skipping a grit level, going from, perhaps, 80 directly to 180, skipping 100-150. However, it’s best to skip no more than one grit level at a time. Skipping over grits will overwork the finer grains and result in a poor final product.

5. Use a segmented platen for even sanding

Sanding should be even and consistent. To achieve this final result, use a segmented platen, which is made of small units that work individually along the workpiece to create even sanding pressure. The segments can be controlled electronically or pneumatically, and they are programmed to operate when needed. This is ideal for sensitive sanding, such as veneer or sealer sanding.

6. When you have “chatter,” check the belt first, then the machine

“Chatter” is a series of faint lines seen across the width of the workpiece. These imperfections can be caused by the abrasive or the machine.

If you have not seen chatter on your workpieces, but they suddenly appear, it may be the belt causing the issue. However, if you are seeing chatter regardless of the belt being used, it’s likely the machine. It’s easiest and often fastest to check the belt first to make sure it is not the cause of chatter. After checking the belt, you can move to machine- or line-related issues, such as worn bearings, the contract roller, or a worn conveyor belt.

7. Find the right product for the project and goal

Not all abrasives are alike. As with grit, there’s a Goldilocks — the perfect abrasive. But it depends on the project (cabinets, furniture, etc.)! It also depends on the goals. For example, are you looking to save money on abrasives or reduce the time needed to sand?

For both the purpose and the goals, brands come to mind. For example, some abrasives are known for their longevity and quality and others are known only for being inexpensive.

See some of our favorite abrasives. If you call our offices, you can also get a recommendation based on what your goals are.

Elevated can help with the right sanding gear

Your company can get high-quality sanders from a team that understands your industrial challenges — Elevated! Our team has decades of combined experience and access to the best products (from Uneeda to Hermes), we’re your source for better sanding. Trusted brands, expertise, great service — it’s why people have been coming to us for sanding ideas since the 1950s.

7 common air compressor maintenance mistakes

This is why you don’t use PVC