Transair piping

If you are installing, modifying, or upgrading a compressed air system, you may consider a variety of different materials for your piping. Options include black pipe, galvanized steel, copper, and stainless steel.

Before making a decision, consider the benefits and drawbacks of aluminum piping. Strong, versatile, and reliable, aluminum piping can bring a fast installation for compressed air systems and better long-term performance for your total operations.

It’s not always the right choice, but for many facilities, aluminum piping is a great option. SmartPipe (by Kaeser) is always a fantastic option. Kaeser is known for their quality engineering. But if SmartPipe isn’t available, we recommend Transair Aluminum Pipe.

Advantages of Transair

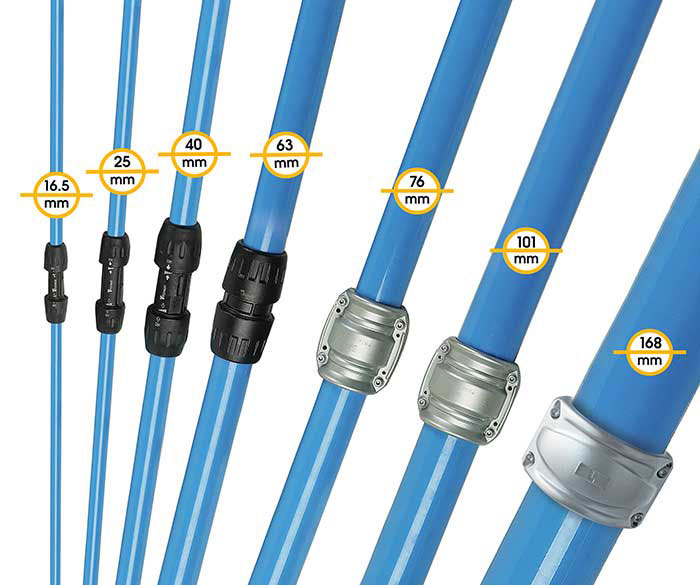

Like SmartPipe, it’s easy to connect and modify, making expansions for your compressed air system and facility faster and less expensive. The Transair push-to-connect system creates a firm hold to make the pipes leak-free. It connects with other piping, too. Plus, Transair comes in a variety of sizes, available in 1/2″ to 8″, and includes a warranty.

Unlike SmartPipe, Transair is readily available and may cost less than SmartPipe. (Contact us for details.)

Advantages of aluminum pipes

Aluminum piping brings a variety of advantages that make it ideal for numerous situations. When you need an affordable, durable, long-lasting system that can deliver reliable air compression, aluminum is often the ideal solution.

Aluminum is lighter than most metals. The mounting requirements and time to install are less than other heavier materials.

Aluminum in general is less prone to corrosion, even compared to stainless steel. Even if there is a moisture trap (which we regularly install on air systems) there will be some water in the system, creating the right conditions for corrosion. This is less of a concern with aluminum.

Disadvantages of aluminum piping for air systems

Although it remains one of the best choices for air systems, this pliable metal does have a few disadvantages. The upfront costs may be higher compared to other metals, which may cause some facilities to choose a different material. (But do your research; aluminum can bring long-term savings when installed correctly.)

There can also be more thermal expansion and contraction, so controlling facility temperatures is critical. Although it meets the needs of most facilities, the pressure rating for some aluminum products may be lower as well.

Your source for high-quality aluminum piping

Transair is a leader in the air-pipe industry. The company has a vast collection of lightweight, strong, corrosion-resistant pipes that come in a variety of sizes. These products bring excellent longevity and typically require less maintenance on compressed air systems.

When choosing your piping, you may need the guidance of an experienced professional to ensure the right pipes for your facility. There are a variety of sizes. (You should get the right size for your compressed air system.) Our installation team can help you determine the best options, add drop points, and more. We make it easy from beginning to end (including start-up).

Contact Elevated Industrial Solutions for expert service on your next installation for compressed air systems. We proudly serve western Ohio, eastern Michigan, and South Carolina. We’ll help you select the right pipes for your specific air requirements, and we’ll be available for installation and long-term maintenance.

Announcing Kaeser’s re-designed BSD series rotary screw compressor

7 deadly sins of compressed air