Case study: reducing energy waste to improve efficiency, save money, and increase sustainability

When Sandvik Coromant laid out ambitious goals for sustainability and energy efficiency, they realized that the air system in their South Carolina facility needed an upgrade. Working with Elevated Industrial Solutions, they were able to cut waste and enhance sustainable practices, all while reducing their overall energy bills.

About the client: Sandvik Coromant

Sandvik Coromant is a manufacturer specializing in metal-cutting tools used in machining applications. Established in 1942 in Sweden, this company is part of the larger engineering group known as Sandvik.

It’s an impressive company with over 100,000 customers worldwide. Sandvik holds more than 1,700 global patents and files 150 patents each year. The group specializes in customized machining tools and digitization; in manufacturing circles they have a well-established reputation for fast production and lasting quality.

As a major global company, Sandvik Coromant leaders are aware of their significant impact on the environment. They are committed to sustainability and energy efficiency, which is why they needed the support of our air-system experts.

The problem: wasted energy from the air system

Sandvik Coromant grew in numerous global regions, including South Carolina, mainly at the Westminster facility.

The existing air system in Westminster had some issues. It was outdated and decentralized, leading to poor energy efficiency and overall air loss, causing the compressors to work overtime to meet the facility’s air needs. There was an issue maintaining consistent pressure, especially when the workload increased. The air within the system also had quality issues, reducing overall product quality and creating further needs for equipment maintenance.

Energy consumption was a particular issue for the facility. Previous studies indicated that the air system was one of the biggest energy users for the entire facility. The company, however, had bold targets for sustainability; wasting that much energy was unacceptable.

Sandvik Coromant needed a partner who could evaluate their needs, plan and build an efficient system, and work with the company to maintain reliability, efficiency, and overall performance. They turned to Elevated, an authorized Kaeser distributor in the South Carolina area, to overhaul the air system and provide greater efficiency with superior performance.

Our solution: a smart, innovative air system

Using an air-study process, Elevated recommended a new primary air system and a smaller secondary system.

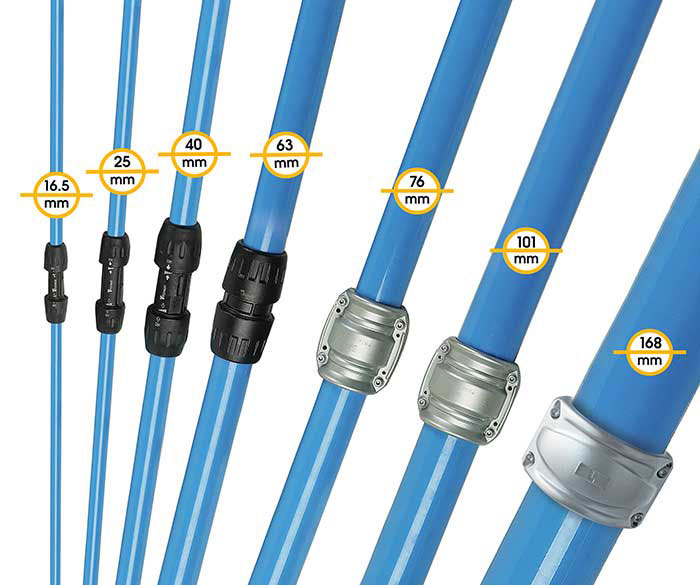

The primary system would consist of four DSD-175 rotary-screw compressors and three TG 980 Secotec dryers. The team would also install a Sigma Air Manager (SAM) 4.0, which pulls operational data and enables stable pressure. To enhance efficiency, the team recommended increased storage and a new SmartPipe distribution system. These components and technologies would improve overall efficiency while significantly reducing wasted air.

The secondary system would be used for extra machining and would consist of two SK 20 rotary-screw compressors. There would be a SAM for this system as well.

The result: sustainability, savings, and efficiency

The original study estimated roughly $80,000 in annual energy savings for the facility. Even for a global manufacturing group like Sandvik, this would be a significant improvement. But in the end, the savings were $90,000 per year – $10,000 more than anticipated.

In addition, facility managers can track usage and make adjustments thanks to reporting capabilities by the SAM unit. Using this critical information, managers and leaders can decrease pressure – as needed – for additional savings, all while delivering on the company’s promise to be more efficient and sustainable.

Exceed your goals with Elevated

Elevated helps you meet your company’s goals. We can increase the efficiency of your facility in eastern Michigan, western Ohio, and South Carolina. Our expert teams can install machines, conduct analysis, and provide additional equipment … just like they did at Sandvik Coromant.

We also offer preventive maintenance at each of our locations to ensure your facility never shuts down, operating at peak efficiency every day.