What’s the cost of an air leak?

What’s the cost of an air leak for your business? Thousands of dollars? If your operations are large enough, could it be in the hundreds of thousands?

Leaks in a compressed air system waste a staggering amount of energy, energy that drives up your already-expensive utility bill. Whether you are the owner or plant/facility manager, leak audits can identify problem areas and, with appropriate changes, significantly reduce your overall energy bill.

But first, you need to understand the true cost of leaks in your air system.

Calculating the cost

Calculating the exact cost of a compressed-air leak can be difficult, as numerous factors are involved. The size of the leak is just one factor. Other factors include the running PSI of your system, the number of tubes, hoses, and pipes, the diameter of pipes, and the number of tools being used. The cost of energy in your area is also an essential factor for calculating the costs of a leak.

While we can’t tell you, at least through this article, how much leaks are costing your business, we can describe the potential for huge losses that come from leaks in your air system so you can help calculate it. The formula, according to Cincinnati Test Systems is:

Number of leaks * leakage rate (CFM) * (kW/CFM) * operating hours per year * ($/kWh)

As an example, Fluid Power Journal, an industry publication that provides a spreadsheet of leak-cost data, provides some key items and costs associated. Depending on the desired PSI, the cost for a half-inch leak can, according to their data, range between $60,005 and $98,970. A one-inch hole can cost as much as $395,879 if maximum pressure is required by the system. And, we should note, this information was published in 2015. As of February 2023, that one-inch hole using an inflation calculator would be more than $475,842.91. Oof!

But, fortunately, there are ways to reduce these costs.

Reduce air leak costs

In 2014, the United States Office of Energy Efficiency & Renewable Energy conducted a study at a chemical plant, working with plant leadership to conduct a compressed-air audit, then following through with a leak-prevention program. The program involves multiple phases, including the establishment of a “Leak Detection and Repair” segment. This phase, which cost $2,500, conserved over 120,000 kilowatt-hours in a single year and saved $9,100. By their estimates, the program paid for itself in three months. This was back in 2014, so it’s dated, but it highlights the potential savings, which are still possible, that come when a plant finds and stops air leaks.

Air or leak assessments are relatively quick and painless. Someone comes to your facility, discusses company goals and concerns, and then begins running some tests to collect metrics. In less than a week, that data is collected and is ready to be discussed.

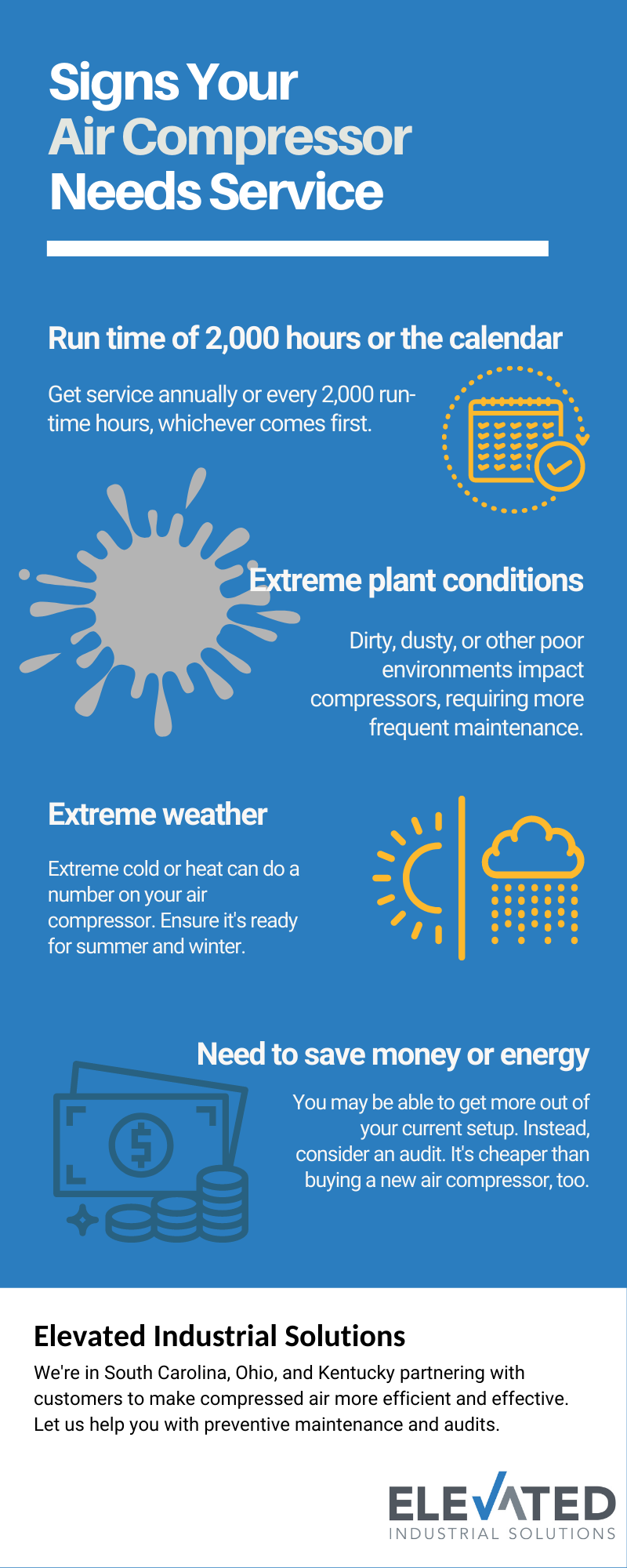

Air leak audits to maintain an efficient system

A leak audit from the experts at Elevated Industrial Solutions is the first step toward eliminating costly wasted energy. Contact our team today and let’s schedule your leak audit as soon as possible. We proudly serve South Carolina, southern and northern Ohio, and southeastern Michigan.