Foam abrasives 101 from Uneeda

Foam-based abrasives – otherwise known as sanding sponges or sanding blocks – have become a popular option for various sanding applications – and they make up some of our most popular products. However, with all the options available, it can be tough to know which will best meet your needs.

In this article, you’ll learn about Uneeda’s foam sponges, their advantages, their differences, and the various technical aspects that could help you choose your ideal solution. Of course, there is no perfect, one-size-fits-all product, so at the end of the day, optimizing your sanding process comes from a balance of knowing the technical aspects of your project needs and the abrasives, as well as some amount of trial and error to find what works best for you.

Foam density

In general, foam abrasives are made from two densities – referring to the “heaviness”/firmness or flexibility/softness of the foam. The two options are soft density, also known as “open-cell”, and hard density, or “closed-cell”.

One isn’t better than the other, rather they are used for different applications.

Soft

Soft-density foam, as you might guess, is more flexible and “squishy.” Open-cell foam will easily fold, flex, and bounce back with no issue or permanent change. This is beneficial when sanding profiles and intricate shapes, such as on crown moldings or contours on cabinet doors, as well as edge sanding. You can manipulate soft-density foam to match any curve or contour you might need to, as the lightness allows the foam to recede and mold to any shape. Soft cell sponges are also great for rounded objects, such as chair or table legs, railings, or newel posts, as they can be wrapped around the workpiece. One issue that sometimes occurs with some soft-density sponges is “grain shed” – in which some of the abrasive grain comes off of the sponge due to the malleability of the foam. This can cause excess grain to be left behind on your surface, while also affecting the longevity of the tool. However, Uneeda’s Ekadiamond sponges, specifically, have been shown to have minimal to no grain shed, making them a high-quality option for this type of sanding. Additionally, because open-cell foam is so soft when sanding by hand, you need to be careful to use even pressure with each finger, to get an even and consistent finish.

Hard

Hard-density foam is made of a thicker foam substrate, which generally isn’t nearly as flexible as open-cell products. Due to the nature of foam, all sponge products have some level of “give”, however, because closed-cell products are much less pliable, they are more suited for flat surfaces, such as inner panels or rails and styles on shaker doors, rather than curved surfaces or profiles. They do have some flex and as such, they can also be used for edge sanding. The denser foam will generally give a better cut rate since the grain will not recede into the foam nearly as much. It will also allow for a lighter cut than conventional abrasives (sanding sheets or discs), since the foam will absorb any pressure from your fingers or vibrations (from a sander). A closed-cell foam block will allow for a consistent finish, even in hand sanding applications, because it will be thick enough to avoid uneven pressure from different fingers/awkward hand positions.

Sanding style

Uneeda’s abrasive sponges are available for two main types of sanding – hand sanding and orbital sander sanding.

Because sponges will offer a softer finish and lower cut rate than regular sandpaper, these products are typically used in finishing applications, such as preparing a piece for stain or paint, or between layers of coating to improve adherence.

Hand sanding

Abrasive sponges are some of the most popular and effective tools for hand sanding (sanding without the use of an orbital or other power sander) applications. While sanding by hand can be tedious, sometimes it is just what is needed to get the best finish. This is especially true for pieces with complex profiles or carvings, which may be too delicate for a sander. In this case, a hand sponge or a sanding block with foam interface pad and traditional coated abrasives could be a great option to get the finish you want. Another benefit to sanding by hand is that it can be more cost-effective than owning and maintaining power sanders – which would be a benefit for lower-volume shops or hobbyists.

Orbital sander

In addition to hand sanding sponges, Uneeda offers various coated foam abrasives as well as foam accessories for the orbital sander. Using a power sander, like the Ekasand Electric or Pneumatic Orbital Sanders, with foam products is a great option to speed up the sanding process in high-volume shops that produce a lot of cabinet doors or other products with curved profiles. You’ll get smooth and consistent results as well as a great finish. Sometimes using an orbital sander can produce swirl marks, especially a 3×4 sander that doesn’t use a random orbit pattern. However, using a foam interface pad with a conventional disc or sheet abrasive, helps to reduce the vibration, allowing the sander to glide more smoothly across the work surface and minimizing the likelihood of swirls. When done correctly, using coated foam abrasives on a sander creates a better, more consistent finish. Plus, it’s much faster than hand sanding.

Uneeda’s foam abrasives

Uneeda offers a variety of sanding sponges for both types of sanding – by hand and using a sander.

| Abrasive | Density | Sandin style and advantages |

| Uneesponge | Hard | Hand sanding abrasive, ideal for flat surfaces and edges, especially for cleaning wood, metal, plaster, plastic, and fiberglass |

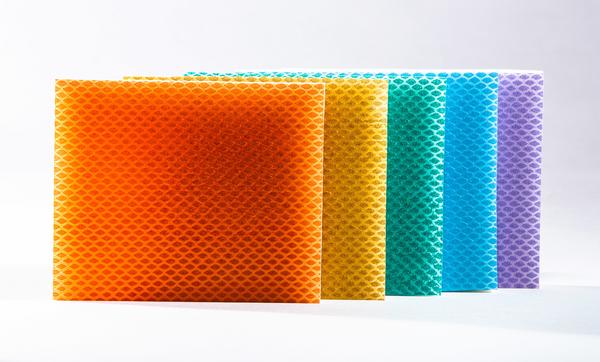

| Ekadiamond | Soft | Hand sponge that’s colorful and creates a diamond pattern |

| Filmtek, Ekastorm | Soft | Hand sanding block that provides consistent pressure |

| Ekasilk Plus | Depends on size | Power sander abrasive with various options, great for stripping, prepping, and finishing as well as for the distressed look |

| Interference Pads | Soft | Power sander abrasive block with hook and loop on both sides |

Elevated sanding options

At Elevated Industrial Solutions, we have a variety of abrasives for every job. Uneeda has unique options, and the Ekasilk is admittedly one of our favorites, but we also carry other abrasives, including options from 3M, Arc, Mirka, Hermes, United Abrasives/Sait, Sia, and VSM. Let us help you get the right product for your sanding jobs.

We also go beyond abrasives and products. Our goal is to be the catalyst for your business to grow. We’ll help you look for efficiencies and to be more effective in your processes.

Get your compressors ready after the holidays

Don’t get fooled – go with the real deal (Kaeser and dealer expertise)