How to choose the right air compressor for your facility

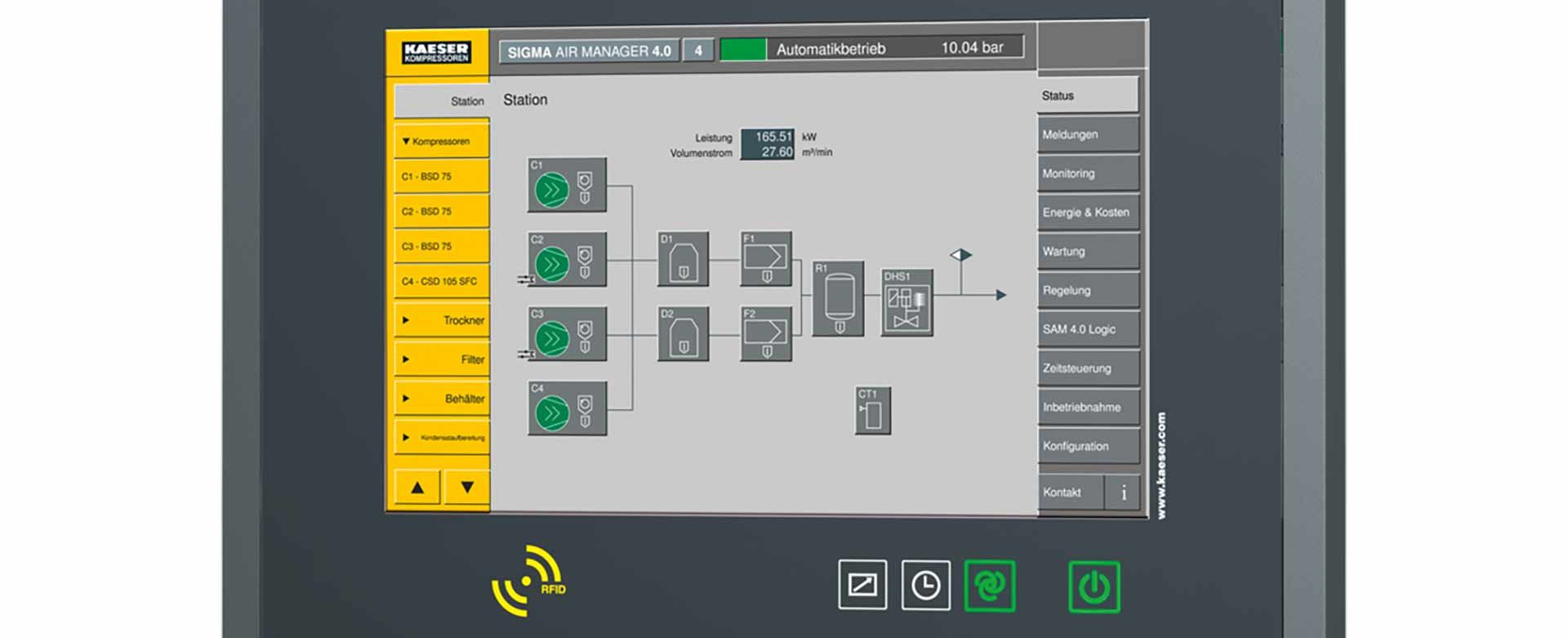

Air compressors are needed equipment for many industrial, construction, and manufacturing companies. It’s the source of energy that runs your production. And be it a workshop or construction site, the right kind of air compressor can make or break your project.

Finding the right air compressor for your job is a balance between a fair price and enough power to ensure high-quality work. The most important factor to consider when selecting an air compressor is your usage.

Certain jobs require a heavy-duty air compressor, while others would benefit from a lightweight, portable system. If you’re using more power than your air compressor supplies, regular breaks will be required throughout the job to compensate.

Along with your usage, you should consider the following factors when selecting an air compressor.

1. Tank size

The duration of time that you’ll be using the compressor dictates the size of your air compressor tank. Longer operations require larger tank sizes.

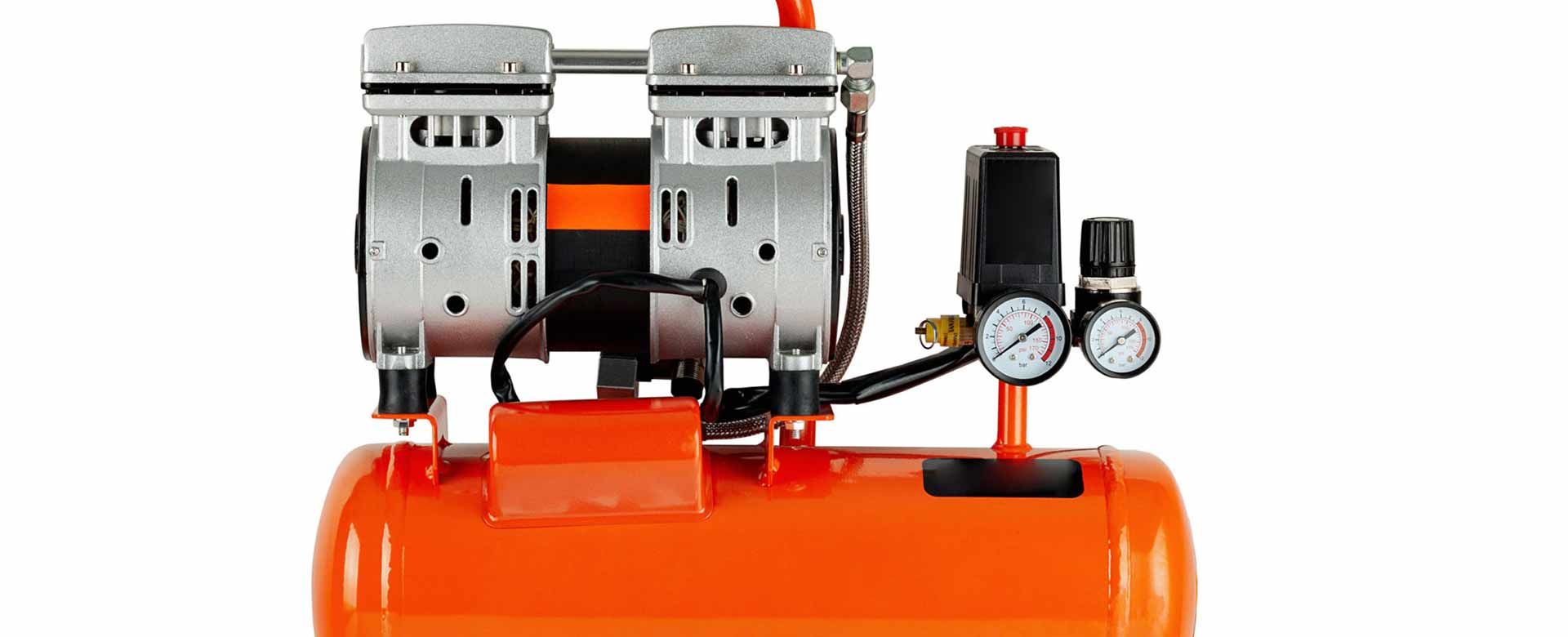

2. Oil or oil-free compressors

Some air compressors use oil to lubricate and cool the compressed air. These compressors are more suitable in industrial settings, rather than medical or culinary settings. Consider the air quality needed at your facility before deciding whether you need an oil compressor or an oil-free compressor.

3. CFM

Cubic feet per minute, or CFM, is how air compressors are rated. It’s crucial to estimate the CFM required in your facility to select the appropriate air compressor. At Elevated Industrial Solutions, we never recommend more power than you need or can handle.

4. Portability

In some places, such as large, established manufacturing plants, stationary air compressors are fine and could be even preferable. But for some jobs, including construction and the use of pneumatic tools (such as drills and wrenches) you may need mobile compressors.

5. Sound level

At job sites that require effective communication, quieter air compressors would be the better choice. The loudest air compressors can produce a volume of 90 decibels, which is difficult to communicate over. It’s also hard on human hearing, even with hearing protection (which would be necessary).

Get a trusted partner to help

At Elevated, we have 35+ years of experience recommending compressed air systems for various environments – from hospitals to dental facilities to automotive manufacturing plants.

If you’re unsure which air compressor to choose for your facility, reach out to us. We’ll survey your site, talk about your needs, and then recommend something to keep your facility up and running while doing the jobs you need to do.